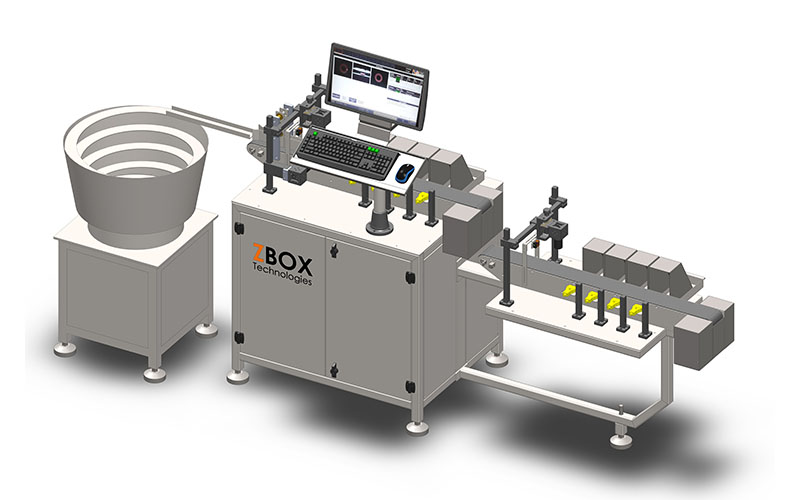

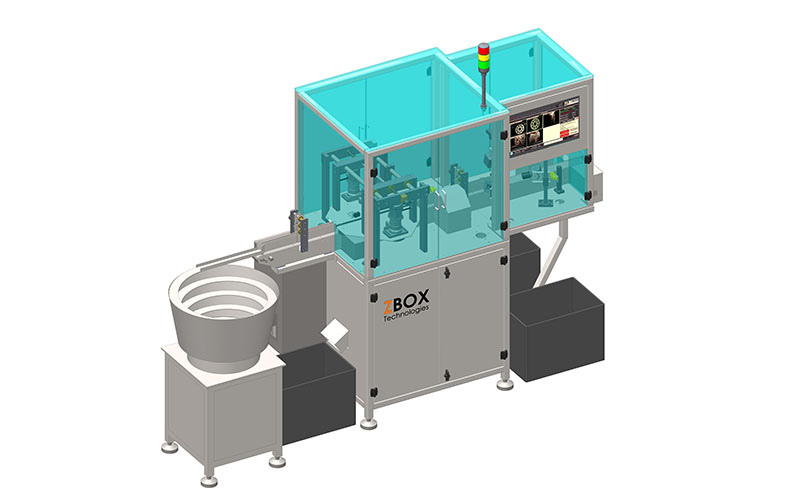

Our optical sorting machines automatically Inspect, sort, grade and classify your manufactured components, Our machines continually sort your products while you get on with the important manufacturing tasks. We help you deliver perfectly sorted products – day in, day out – giving you 99% quality inspected components that your customers will satisfied.

More about Optical Sorting

What is Optical Sorting?

Optical sorting is the process of using machine vision and vision system technology in real-time to assess the quality of a component at high speed. Optical sorting machines normally use a combination of automation machine vision algorithms and latest generation advance algorithms to sort product separates into good and bad collection bin is to saves man power and resources, while also providing a higher level of inspection by the use of computer vision technology to make decisions.

Why customers need Optical Sorting?

There are many reasons to buy optical sorting. Defects can originate in the original manufacturing process, for example, surface challenges, cracks, dents, dimensional errors, and missing processes can produce a product which is faulty. In addition, routing of a process through the factory may introduce further defects such as mixed batches, foreign material and cause defects during other processes.

Optical Sorting Machine Suitable for

Any small components, produced in high volume, at speed, can be inspected using probe vision software with very high-speed optical sorting machines. From fasteners, small parts, plastics, components, medical devices, metal objects, through to washers, O-rings, studs, caps, electronic parts, rubber and plastic moulds – all similar products can be inspected using optical sorting and machine vision technology.

Smarter Inspection

Our High speed optical sorting machines is very latest vision inspection algorithms with ultra-clear images make your most important defects visible. We intercept and reject failed parts at high speed, discover shifts in quality, and provide quality assurance through your production cycle.

Statistics and Data

Detect Unanticipated Defects

Our optical sorting machines help engineering, quality and operations save time, monitor production and increase, our systems detect unanticipated defects to gain control over defect rates.